Predictive Analytics

Fleet Telemetry

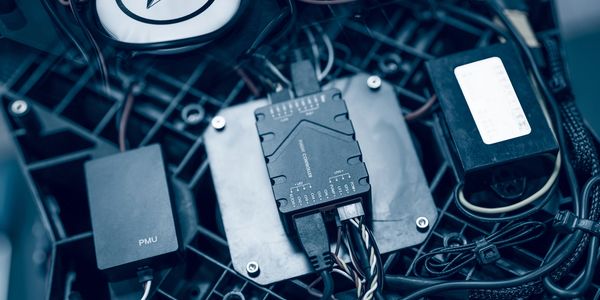

We turn raw fleet data into a clean, reliable foundation for maintenance and readiness analytics. That includes securely capturing telemetry from vehicle buses and sensors, validating it at the edge, and moving it into cloud or enterprise environments where it can safely power predictive models and condition-based maintenance strategies.

Physics-Inference AI

Once telemetry is flowing, we apply a blend of predictive analytics, machine learning, and physics-inference AI to understand how assets behave under real-world loads. Our models respect the underlying physics of the system—so predictions are not only accurate, but also explainable to engineers and maintainers.

Rendered in Dashboards

- Failure-pattern discovery from historical telemetry and maintenance data

- Remaining Useful Life (RUL) and risk scoring for critical components

- Physics-inference / physics-informed models using load, temperature, vibration, duty cycle

- “What-if” scenarios for changes in usage, environment, or mission profiles

- Continuous model refinement as new telemetry and fault data arrive

Diesel Engine Digital Twins

We build physics-based digital twins that make hidden bottlenecks visible. By replaying historical maintenance and usage, the twin calibrates to real behavior, learns degradation patterns, and lets you simulate real-world scenarios—temperature, load, terrain, operating hours, and wear—even when OEM channels are blocked by proprietary encryption.

The result: a validated, simulation-derived dataset that fills the gaps left by encrypted OEM data—so your existing predictive models can forecast failures with confidence and actionable lead time.

What we deliver

- Twin Commissioning: calibration + validation using historical maintenance/usage records.

- Physics-Based / Physics-Informed Digital Twin: bottleneck discovery + scenario simulation + synthetic feature generation for PdM models.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.